Now that the engine is fully refurbish it was time to check out the diesel tank.

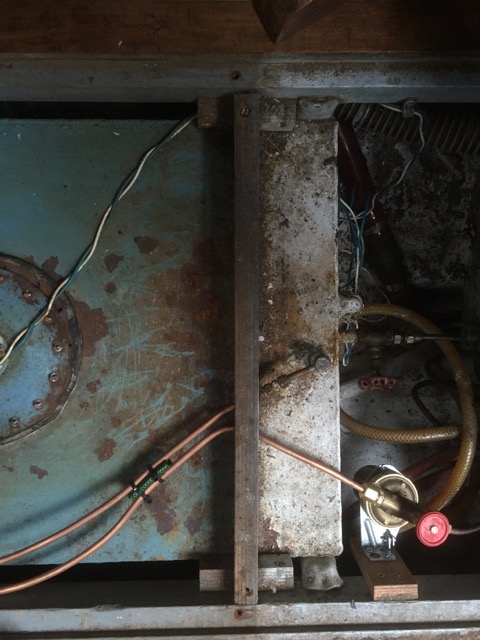

The Seadog still had the original steel tank from 1974 which turned out to be in a really bad shape.

The tank had two inspection holes on the top to check out the inside, so at first we inspected the tank through those holes. Strangely enough the tank was filled to the top with diesel, which appeared to have come out of nowhere. Two years ago the tank was completely empty and no extra diesel was added since then. The only way that diesel could have gotten inside the tank was through the overflow pipe of the diesel heater, which is connected to the diesel tank of the engine. Which means the regulator of diesel heater is malfunctioning.

After pumping out nearly 160 liters of diesel it was clear that the diesel inside the tank was contaminated. The diesel was more murky and darker than usual, plus there was a lot of sludge left after draining the tank, which indicates diesel bacteria. Now that the tank was empty we could lift it out of the floor and take it outside for further inspection. After cleaning the tank from the inside and the outside it became clear how badly corroded the steel was. When cleaning the outside to the tank with a vacuum cleaner for a second time the suction even broke a hole inside the bottom of the tank. In one way I was very lucky the tank did not leak all of it’s 160 liters of diesel inside of the boat, but the sad part is of course the tank was beginning to look beyond repair. It would have been a lot of work to repair and clean this tank. And even if it was fully restored it still would have been a steel tank (not stainless steel), which would eventually start to have the same issues all over again.

So the decision was made to get a new diesel tank. One problem though, I could not buy a regular tank from a marine shop. The tank needed to have a custom shape in the form of the hull of the Seadog. After some research I also decided not to go for a stainless steel tank, but a special kind of plastic tank. These plastic tanks seem to have some superior characteristics over their steel counterparts. For one, there is less change of diesel bacteria forming, because the plastic parts have less change of forming condensation inside the tank. There are a few companies in The Netherlands that can build these custom diesel tanks for marine purposes, and after shopping around I found a company in Koudekerk aan de Rijn which came with the best offer. The company is named Liquid Storage (http://www.liquidstorage.nl) and they make all kinds of storage tanks. There service was impeccable and I can really recommend them to anyone who needs new tanks aboard their ship (also for drinking and wastewater tanks).

We brought the old thank to this company where they used it as a mold to create the new one.

While waiting on the new diesel tank I cleaned the bilge underneath the floor where the tank used to be. While cleaning there I found out there was a lot of wasted space besides the diesel tank that was unacceptable before (with the tank in its place). When living aboard even a little extra storage space is always welcome. To make this space accessible I needed to saw the floor up into pieces to create hatches and add some bulkheads to divide the space up. After that was done I painted the bilge and the new storage spaces with two layers of bilge paint.

Because there was some more time before the tank was finished we also painted the deck with special non-skid paint and mounted the windlass, plus the guard rail. The diesel heater has also gotten its own overflow tank (with its own gauge), so that the old contaminated diesel can be burned in the diesel heater this winter without any of that nasty stuff getting inside the new tank. The issue with the diesel heater regulator was also solved so it should not be overflowing anymore.

All the hoses to and from the tank (plus all the filters) where also replaced, so everything connected to the engine is now brand new.

And voila, new storage spaces, clean bilge, new overflow tank, new diesel tank, and a freshly painted deck.

With the guard rail back in place the Seadog is starting to look more and more like a real sailboat again. After more than 5 years inside the harbour, the first trip is almost becoming a reality.

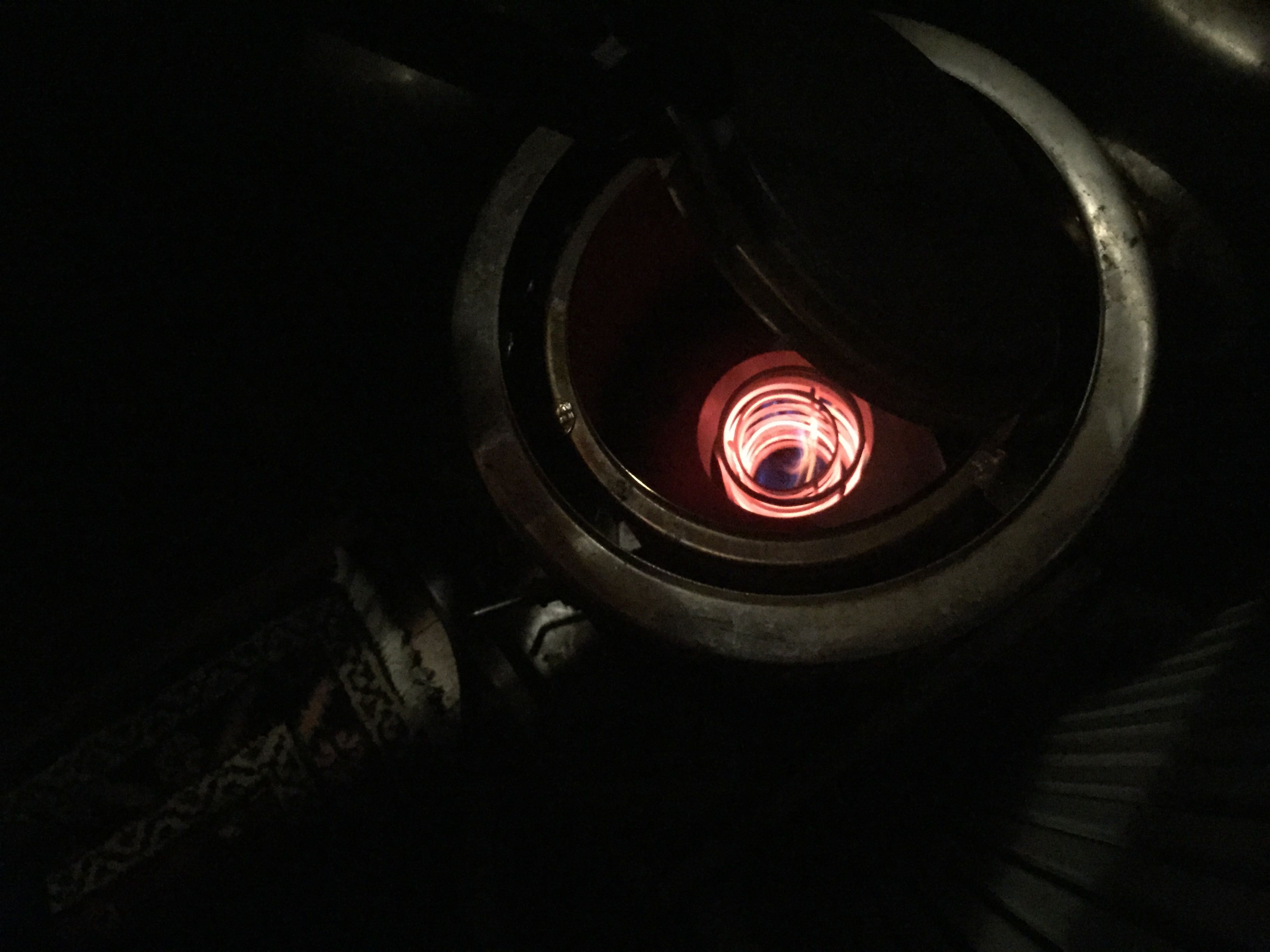

The next step will be connecting all the wiring, hooking up the battery and if all goes well starting the engine for the first time.

A washing machine aboard the Seadog

A washing machine is a luxury item and thus not a “must have” onboard a sailing vessel.

Most people just take it for granted at home, but aboard it’s definitely not standard.

Despite that fact, to make life as easy as possible I decided that the Seadog could have one.

I already had the perfect spot figured out. Only problem was that it really needed to be an extremely small machine to fit it in there.

If I could get a machine with the right dimensions, then it should fit inside the bathroom, replacing the laundry basket.

Dirty laundry could then be put directly in the washing machine and when it’s time to wash, just add detergent and startup the machine.

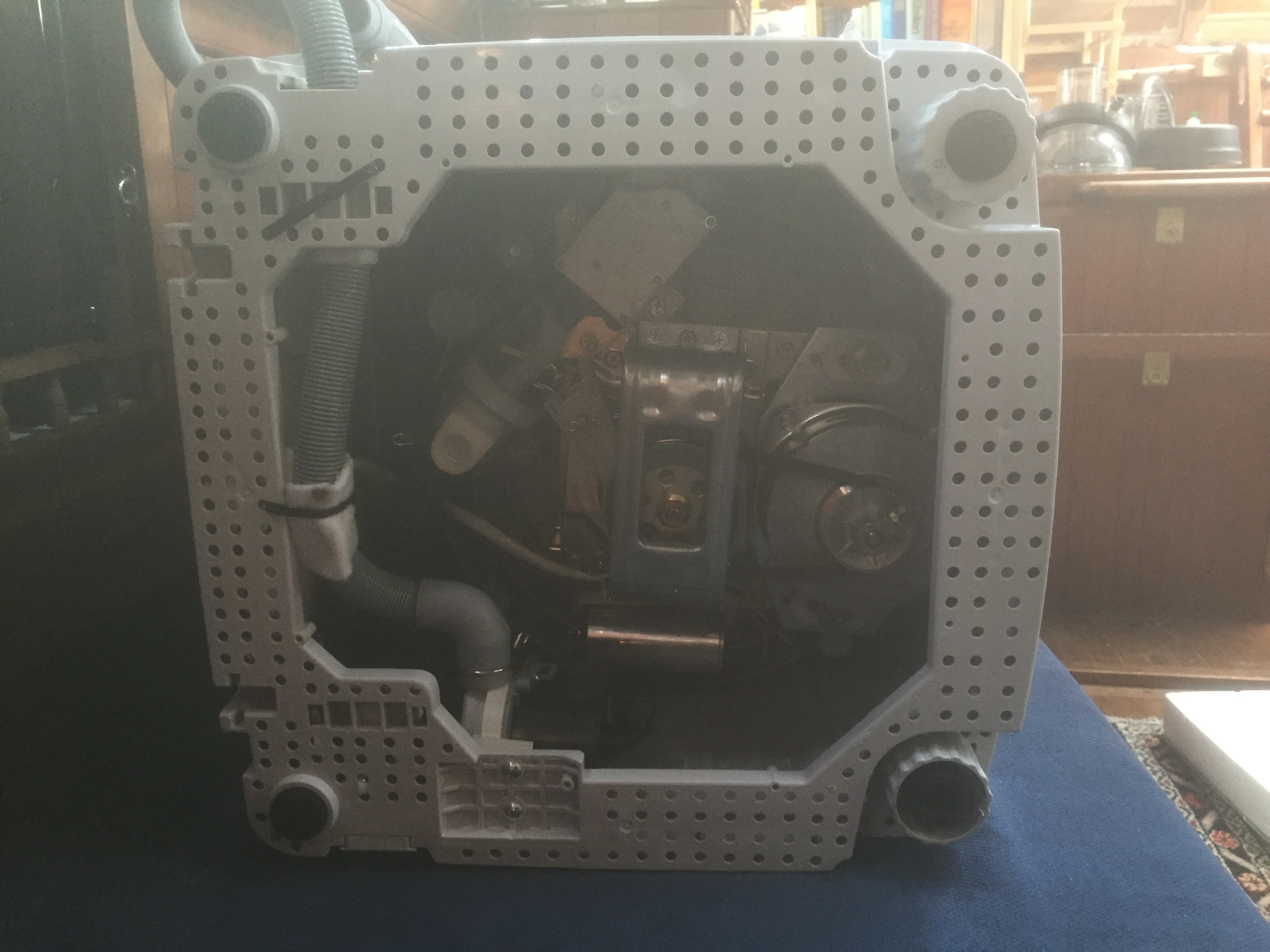

Well, after some research I found the perfect fit. This machine does it all. It washes, it dries the cloths, has multiple programs, and has the door on top of the machine. Only 180 euro,- and exactly what I needed.

The bathroom did need some minor remodelling and a sturdy wooden frame to support the machine, but in one day after receiving the machine it was ready to spin.

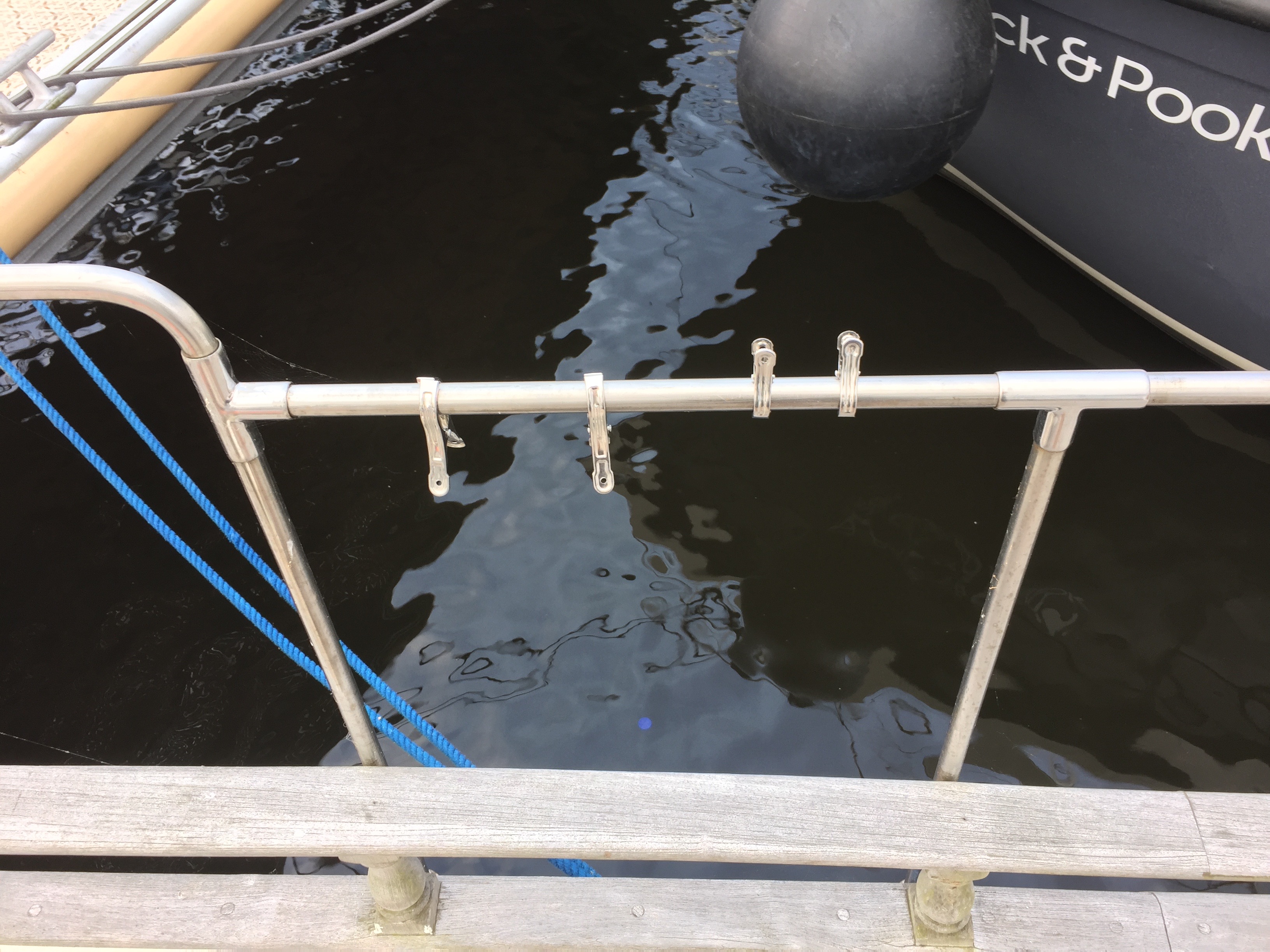

Drying your cloths aboard a boat can be petty tricky because of the fact that if they drop they might fall into the water, sink, and drown.

So I also ordered some special stainless steel clothes pins that are perfect to hang cloths on the guard rail of a boat. Check out all the photo’s below.

Repairing a leaking watertank

The Seadog has two 150 liter water tanks. One on the starboard side and on the port side. Now almost one year ago the water tank on the port side started to leak its precious water into the bilge of the ship. So that tank was drained of it’s contents and was put out of commission for a while.

In wintertime all of the water taps on the pier are disconnected from the main water supply to ensure that they don’t freeze and get damaged. The Seadog is still disabled and can’t go anywhere (because the engine is still not in working order) so we can’t go to the main tap to fill up the water tank(s).

This means water usages aboard the Seadog in wintertime is restricted to as little use as possible. A mobile water tank is used to get drinking water from the main water supply, so that’s not really an issue. But for doing the dishes etc. it’s nice to have a full water tank, and of course in the ideal situation this should be both water tanks.

So I had kind of a deadline on which the leaking water tank should be repaired and operational again, because I needed to fill both tanks before the taps on the pier got disconnected.

First we (my dad) tried to weld the leaks (there seem to be more than one), but that did’t work out to well and after a few attempts it almost looked like the tank was leaking even more.

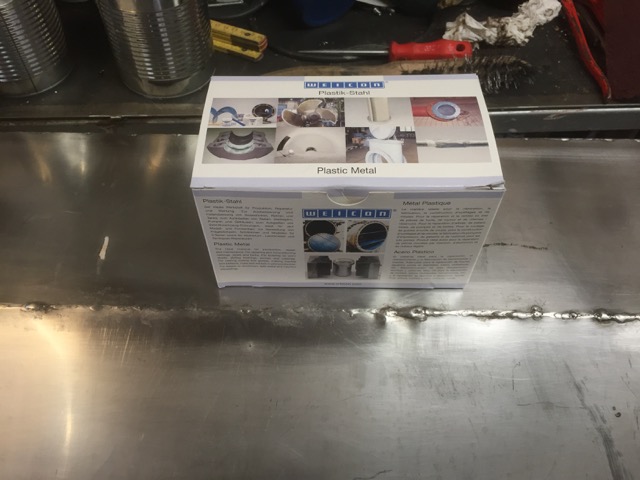

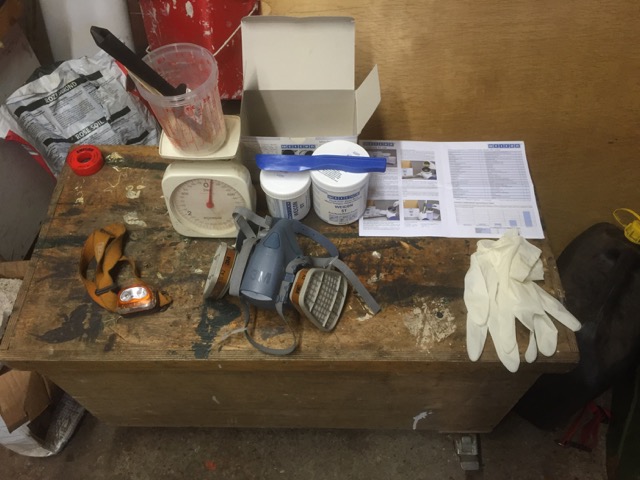

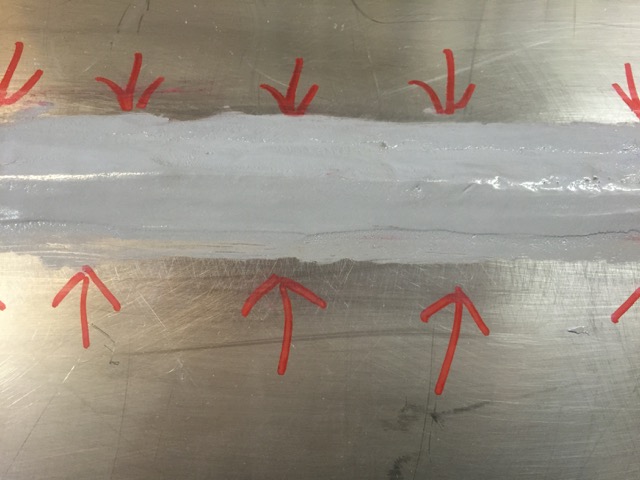

So I turned to my trusted ally; epoxy resin. This time a special kind of epoxy was used, one that was purposely created to repair industrial metal objects. This stuff can even be used to repair objects that need to withstand tremendous pressures like propellers, pumps, pipes, and of course tanks. It’s called WEICON Plastic Metal (http://www.weicon.com/pages/en/products/adhesive/2c-adhesive/plastic-metal.php) and can even be used to repair broken tools etc. and after correct application can be drilled, milled, ground and or filed.

It’s quite expensive, but then you do know for sure you got the right stuff.

Of course I first needed to disconnect and remove the tank and transport it to my parents shed where I could clean and prepare the surface before applying this “plastic metal”.

It did take a few tries before all the leaks where properly sealed and in total I might have been working on this “little” project for three to four weeks before the tank could be put back in it’s place. But lucky for me that was just in time before the water taps were disconnected, so all in all it turned out very well. The tank has been in use for almost three months now, without any leakage so I guess it was a great success indeed.

New diesel tank for the heater

All of a sudden there was a lot of diesel in the bilge of the boat (not good)! It turned out that the original diesel tank for the diesel heater was so badly corroded that it the bottom started to leak. I already planned to replace that diesel tank for a bigger one. There are two wasted spaces at the far left and far right at the back of the boat where I planned to place the new diesel tank. This turned out to be a lot more work then I hoped, but it does free up a lot of space, plus now the tank for the heater is big enough for almost two weeks off heating the boat without the need to refill the tank. Also I made the refill cap for this tank much easer to access and I will now be able to install a diesel level sensor with a gauge indicator, so I can always see the diesel level in this new diesel tank. Photo’s will be added later on.

A new bed for the captain

Winter has come ones again, so the work outside has been grounded to a halt. I love sleeping aboard and find sleep very imported ;-). But the mattress on which I was sleeping was not a very good, so it was time to do something about that. I found that there was enough space left for some expansion of the main bed so that a standard mattress size could fit in that space. So after some sawing and pushing and the like, a brand new mattress could be placed inside the Seadog. I bought a NASA Memory Foam mattress. These mattresses are expensive but are ideal for when living aboard. They absorb little to know moisture and more importantly sleeping on these things is extremely nice. Also, here are some random pictures of live aboard Seadog in wintertime.