Prepping the second mast and the navigation equipment (testing out very old radar)

Work on the fridge / freezer box is still underway, but a second project has also started this past month. The mizzen (second) mast has been lying in wait for almost 2 years, and the time has finally come to prepare it for painting. Also all the navigation equipment needs to be in order so those can be mounted on this mast. The mast has now been sanded and the first layers of paint (primer and first layer coat) have been applied. The temperature plummeted way blow zero (see pictures of the Seadog in the ice below this post), so painting has come to a hold. But with a little luck we can start painting again next week.

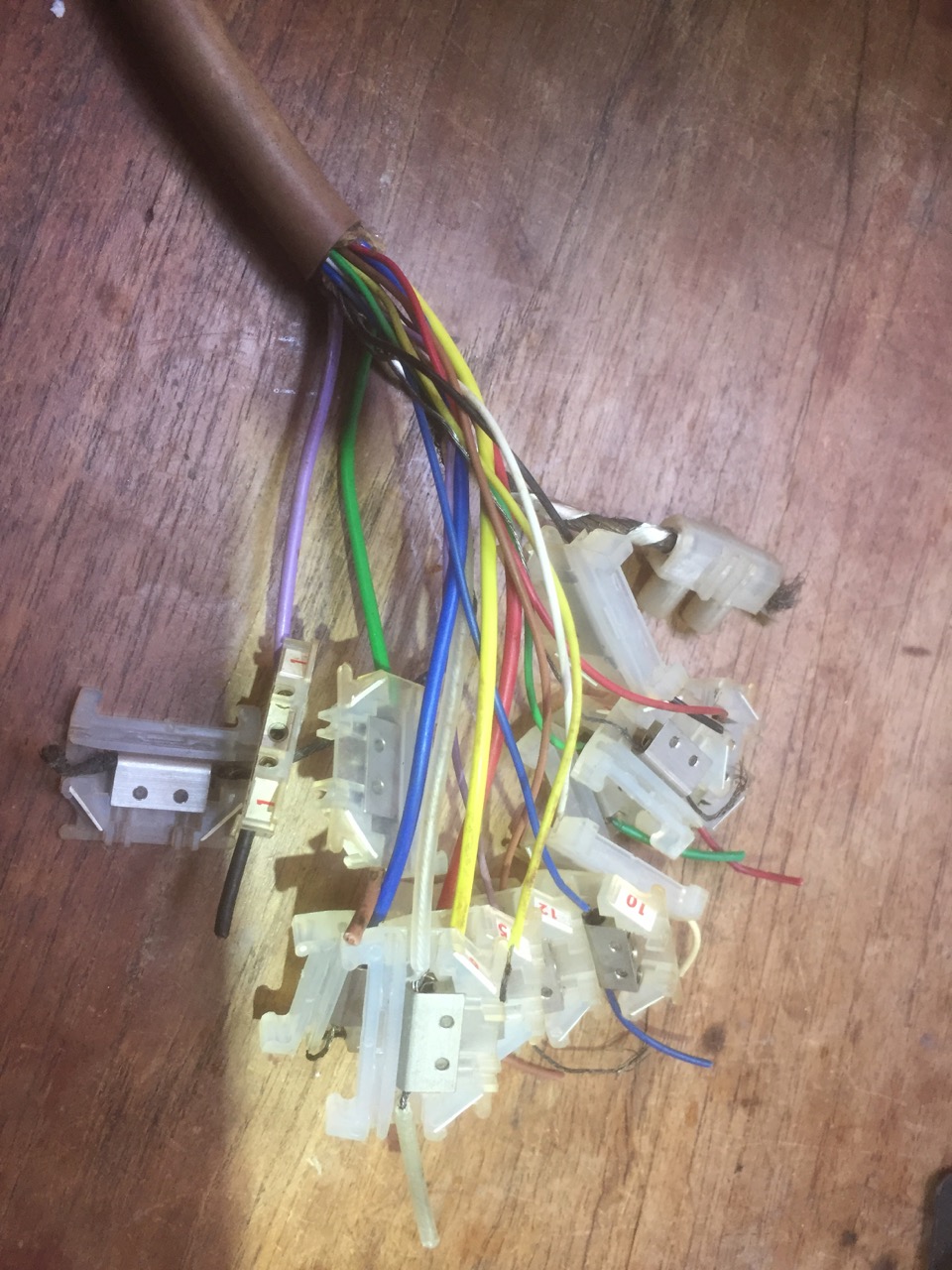

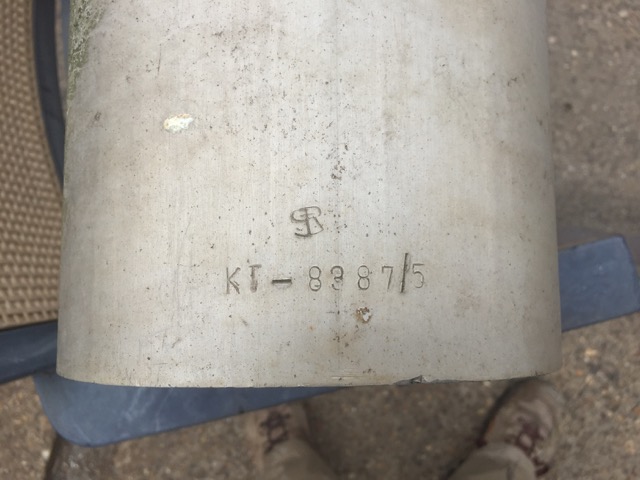

I was lucky enough to get a free (be it, rather old) radar system from a friend of my dad. After some due consideration I decided that if it worked I would install it on the mizzen and not bother buying a new (and very expensive) radar system for now. And lo and behold, after some tinkering and even a little guess-work with the wiring, it seems the system is still operational.

Seadog in the ice….

Hoisting the mast onto the boat and the first real sailing trip

Although I kept and stored all the old rigging to reuse with the new mast, I still decided that in the end it was a better to just buy completely new rigging.

Sure, it costs a lot of euro’s to do so, but this way I can be sure that when the winds are blowing strong the mast will stay on the boat and nothing will break (which would have dire consequences when under sail).

I hired a company to do all of the rigging onside (at the marina), which meant that within 3-4 hours the mast was standing on the boat and all the rigging was done.

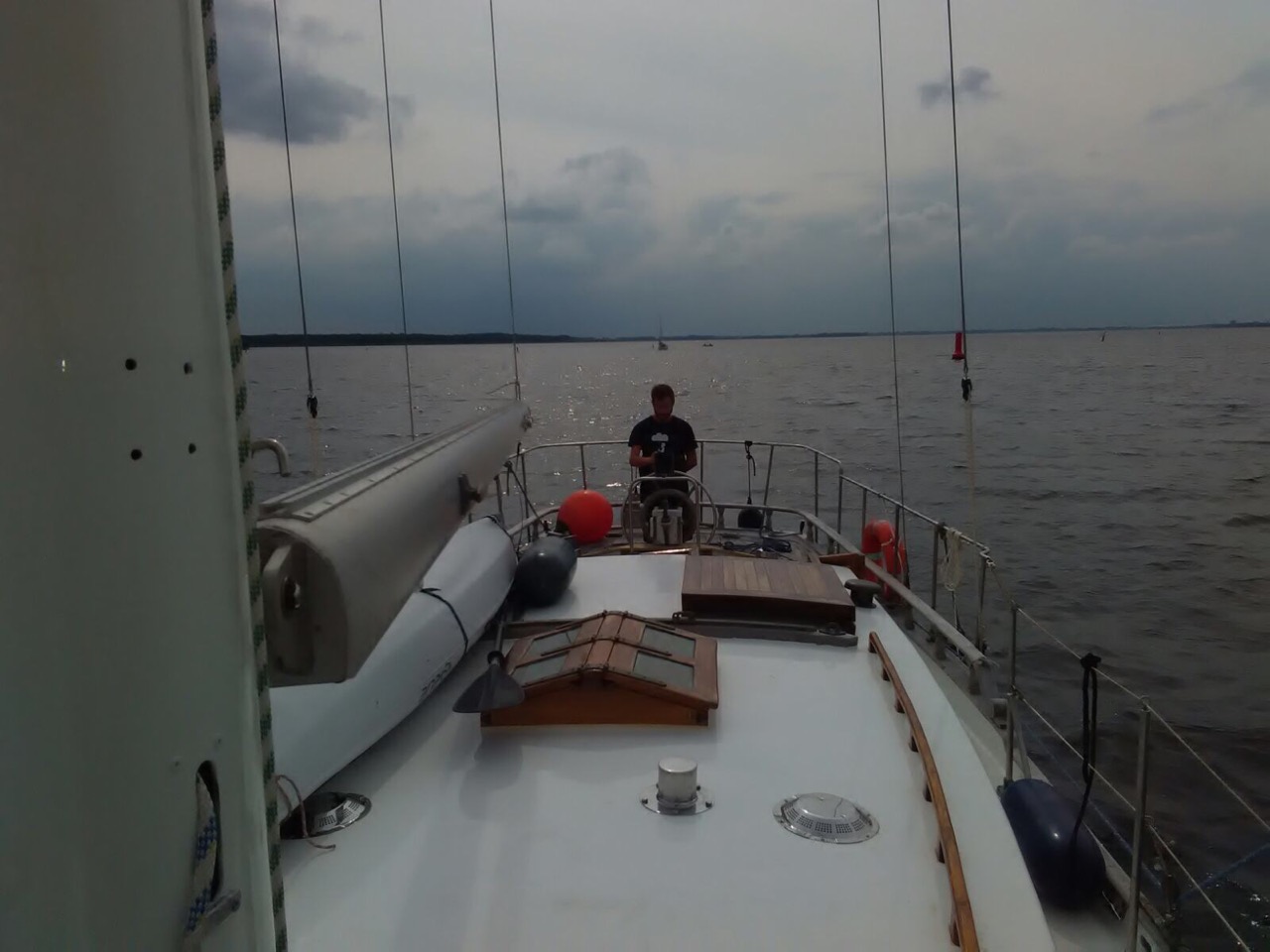

On the same day we took the Seadog out to the lake and hoisted up the jib (front sail). And even with wind speed’s of only 2 Beaufort Seadog was going quite fast.

We couldn’t yet take up the main sail because not everything was ready for that yet. But a few days later we also took up the main. That day there was even less wind, but Seadog still kept on moving. And at the end of the day wind speed’s went up to 3 Beaufort and we were speeding through the water!

The mast hight for the Seadog now is 12.65 meters, and the bridges at the Gooiermeer have a hight of 12.80-13 meters.

Which means it’s going to be quite intensive every time we go under the bridges. Especially if there are big waves, but the first test runs went good, so I guess there’s nothing to worry about….

As always there’s still a lot to do, but from now on it’s also time to go sailing now and again 🙂 (finally)!

Painting the mast and building a custom mast foot

It’s taken more than a few weeks (more like a few months), but the Seadog can Sail!

We had to build a custom mast foot and I decided to paint the new mast white.

It’s not really necessary to paint an aluminium mast, and it’s also not easy because paint does not want to stick to aluminium. But I’m very happy with the result and this means I can also paint the second mast with the same color white to make it look identical to the main mast.

See some pictures below of the process. The next post will show when the mast was hoisted onto the boat and the first time we took here for a sail.

Building custom mast foot

Painting the mast and mast foot

Getting a main mast (and the first real voyage)

A few weeks ago my father found a secondhand aluminium mast that would be perfect as the main mast aboard the Seadog.

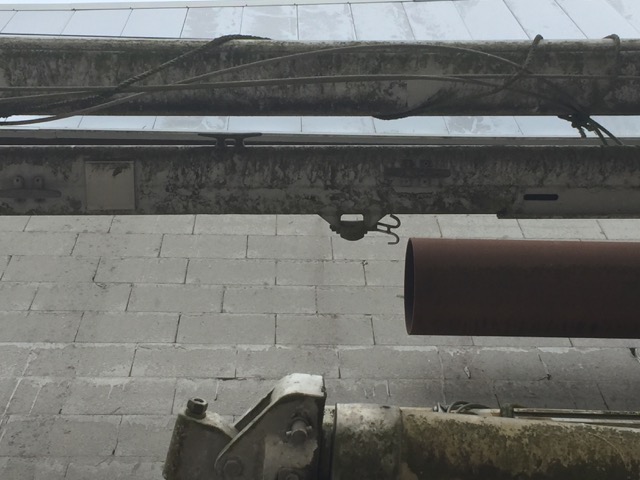

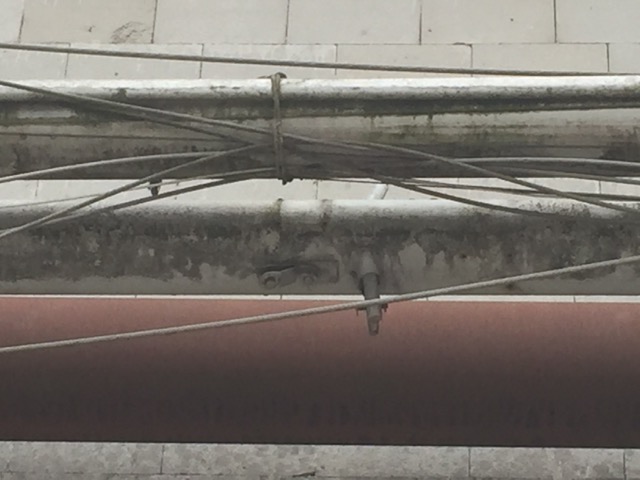

It has been laying around besides a warehouse at a shipyard for more than 15 years. But it actually has never been used before, so structurally it should be as good as new.

Also, this mast is build extra sturdy when compared to most other masts of this size.

The downside is that there came no rigging and very little fittings with this mast. Plus it’s still about 1.5 meters to long and looks a little dirty (see photo’s below).

But we decided this was the way to go.

We first went to Medemblik (where the shipyard was located) to inspect the mast in person and make a few photo’s and decided if it was doable to use this particular mast aboard the Seadog. Conclusion: it could be done.

Because the warehouse was located at a shipyard, we could go and fetch the mast easily by water with the Seadog. Or so we thought….

The weather forecast for the weekend we planned to go and fetch the mast was all but mild weather, but we decided to go anyway.

Turned out to be a pretty nice (be it a little bumpy) journey and also a good test to see how Seadog does in hard winds (on only the engine).

There where a few engine troubles along the way, but this turned out to be because of an empty diesel tank (and a malfunctioning tank gage / vlotter).

The journey back (with the mast tied securely to the boat) turned out to be with the wind at our backs and luckily not as bumpy as the first two days.

After three days we where back in the home harbour and work could begin to prepare the mast for use aboard Seadog.